MWM

Threaded stud weldingBolt welding

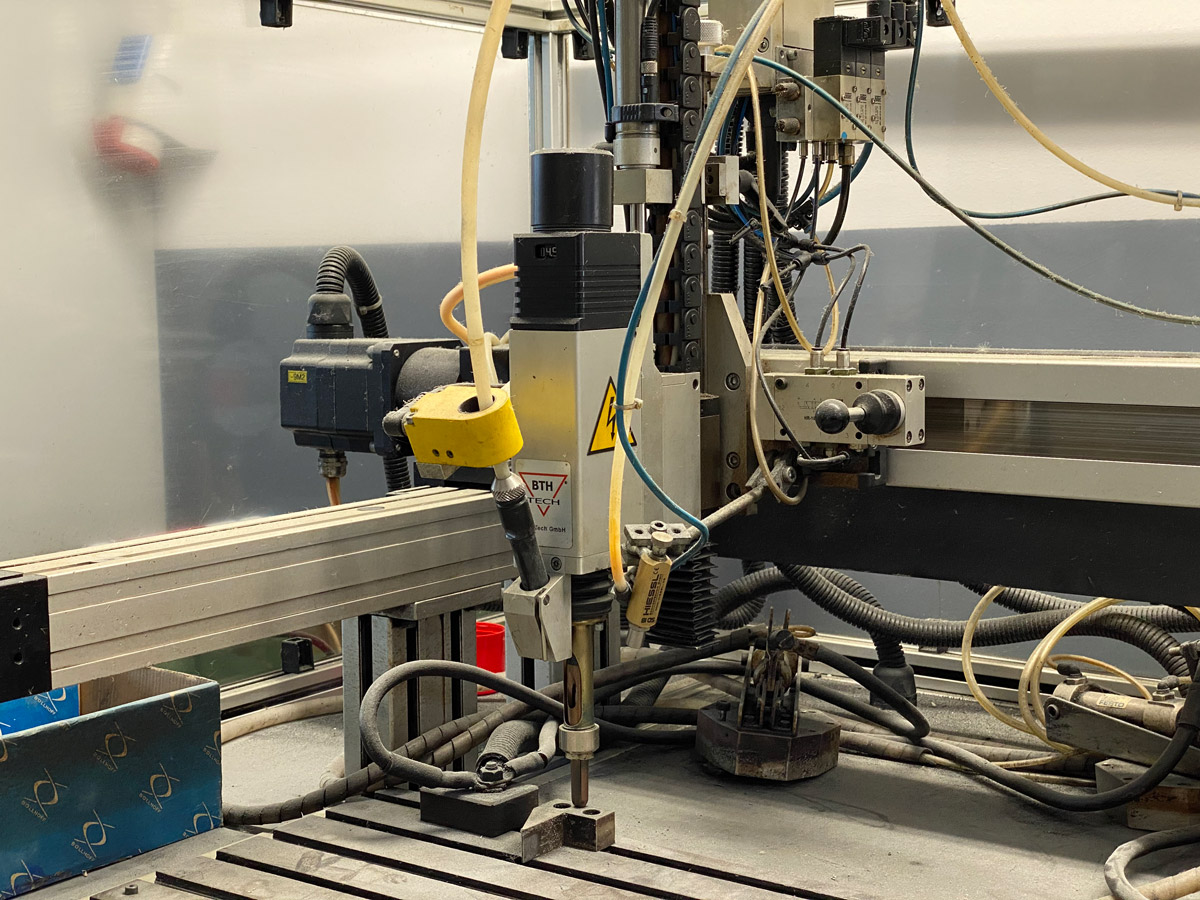

CNC machine - precise - inexpensive - fast

CNC stud welding machine

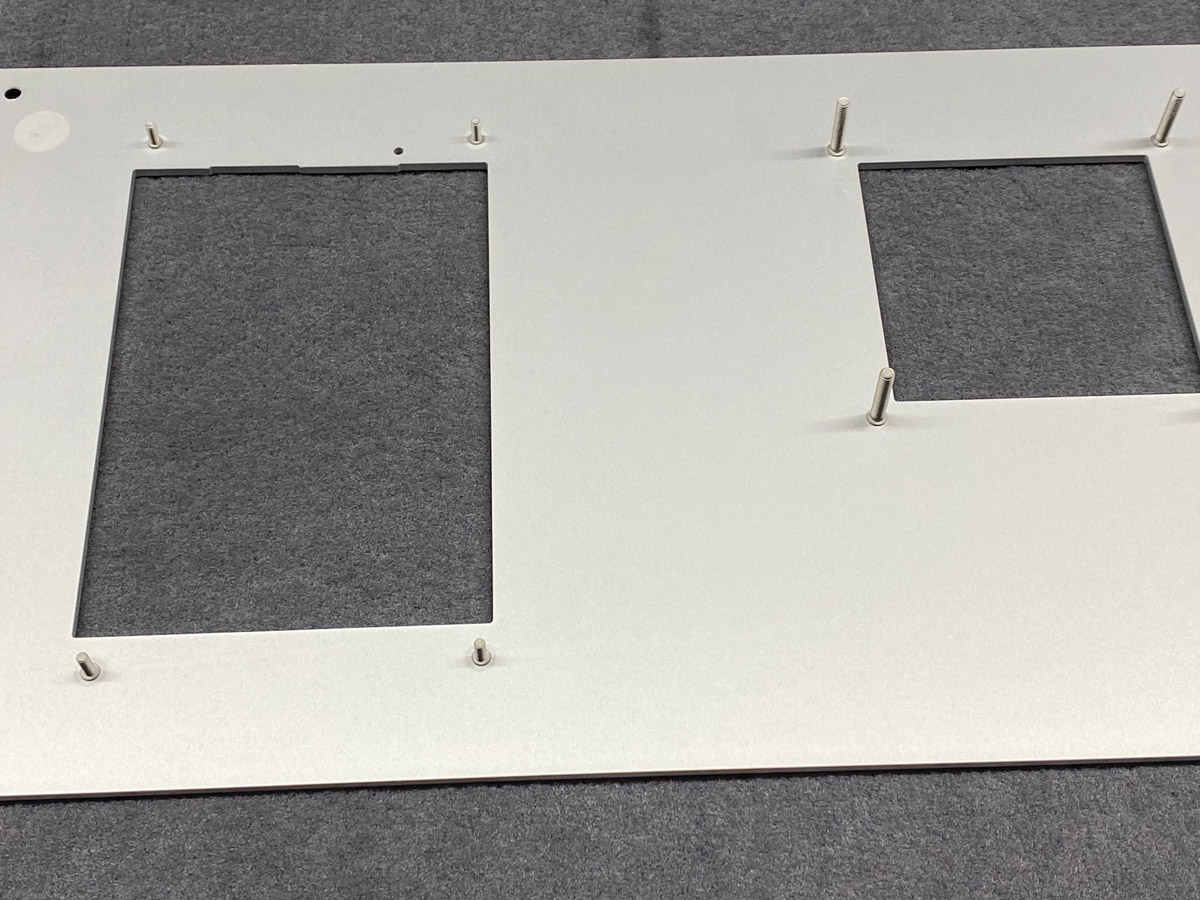

Large processing area

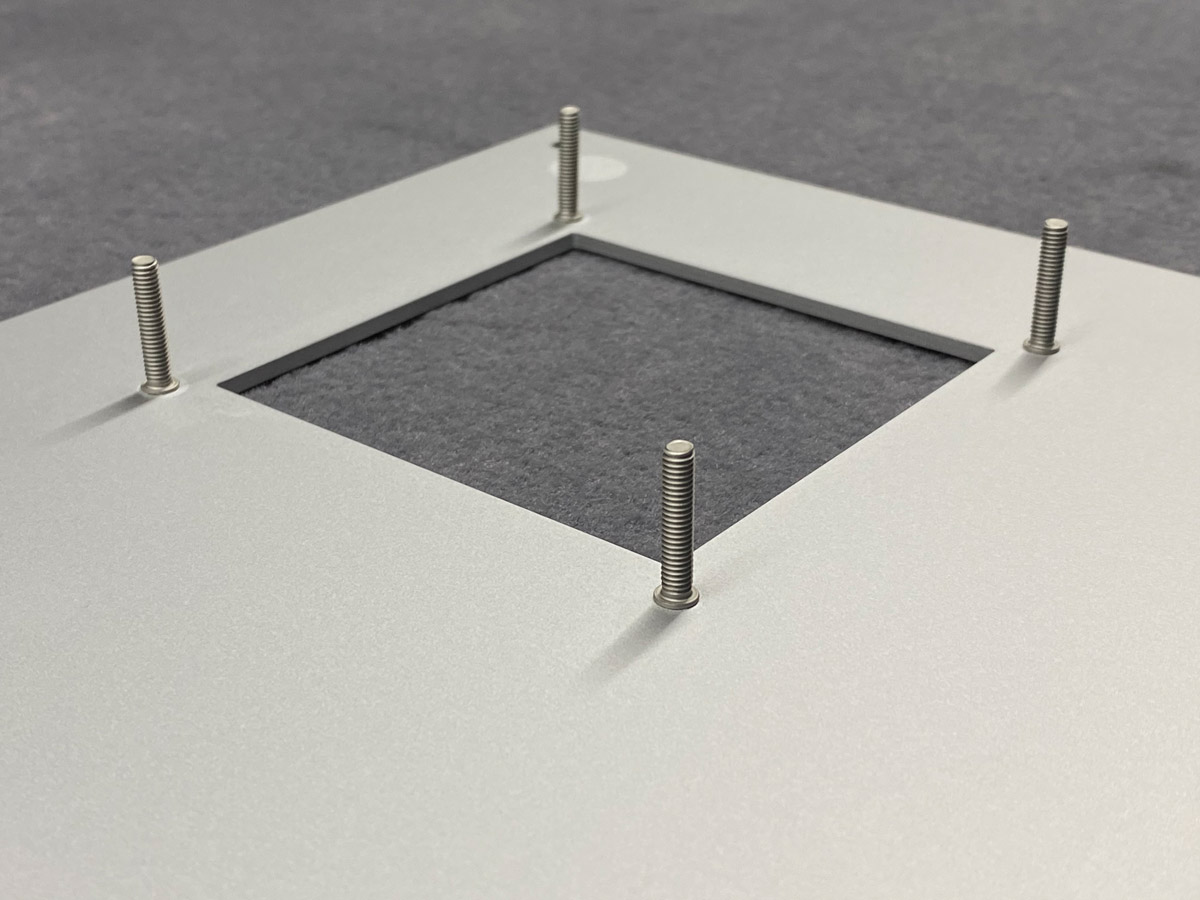

Product detail

FAQ - Threaded stud welding

What is threaded stud welding?

Threaded stud welding is a process in which pin-shaped metal parts (e.g. threaded studs) are welded onto metal workpieces. This can be done using processes such as drawn arc stud welding or capacitor discharge stud welding, in which an arc is generated that melts the surface of the workpiece and the stud, creating a permanent connection.

What are the advantages of welding threaded studs?

Welding threaded studs offers very high strength, as the stud and the workpiece are connected over the entire surface. The process is also very efficient, as no post-processing is required, and threads can be applied in hard-to-reach places where other fastening methods would fail.

Which materials are suitable for welding threaded studs?

Alloyed and unalloyed steel, aluminium and brass are particularly suitable for welding threaded studs. It generally makes sense to weld similar materials together, but other combinations are also possible.

What processes are available for threaded stud welding?

There are two main methods:

Capacitor discharge (CD process): A very fast process that is particularly suitable for thin sheets as the heat exposure is minimal.

Arc welding (ARC process): Uses drawn arc and is more stressful for the sheet metal, but more flexible to use with different material thicknesses.

What are the challenges when welding threaded studs?

Challenges can include warping of the sheet metal due to heat, the need for corrosion protection for different materials and the potentially high cost of the process. It is important to determine the correct parameters in advance, such as tightening torque and strength class, in order to achieve optimum results.

Where is threaded stud welding used?

Threaded stud welding is used in many areas of metalworking, including vehicle construction, the electrical industry, apparatus engineering and construction. It is particularly suitable for applications where thin sheets are used or high precision is required.

Can the welding of threaded studs be automated?

Yes, the welding of threaded studs can be automated, which is particularly useful in industrial applications to improve efficiency and increase the number of pieces per minute.

MWM GmbH & Co. KG also offers other mechanical services in addition to threaded stud welding:

▪ Cutting/sawing

▪ CNC processing

▪ Engraving

▪ Punching

▪ Press in threaded bolts

▪ Laser labeling

▪ Bending

▪ Welding

Contact

MWM GmbH & Co. KG

Hüttenstraße 12

59759 Arnsberg / Germany

Phone

+49 29 32 / 4 75 98 - 01

Fax

+49 29 32 / 4 75 98 - 10

E-Mail

info@mwm-arnsberg.de

About MWM

MWM sees itself as a system supplier in the production of goods and the processing of components made of aluminium, stainless steel, brass and other non-ferrous metals.

We offer our customers full-service solutions in many areas, including the procurement of the necessary raw materials and processing through to surface finishing and subsequent assembly.

Tip

MWM Design

Real stone veneer for indoor and outdoor applications. Find out more now.

© 2023 MWM GmbH & Co. KG • Hüttenstr. 12 • 59759 Arnsberg • info@mwm-arnsberg.de